R & D

Research and Development

Procedure Qualification and Emerging NDT Techniques

To meet the governing codes and standards, procedure qualification and qualification of emerging and alternate NDT techniques developed through case studies, providing reliable inspection results for our clients.

Developing NDT Techniques for Specialized Inspections

Grounded in the basic principles and theory of nondestructive testing methods, Mandina’s Inspection develops creative and innovative solutions to the complex inspection needs of our clients.

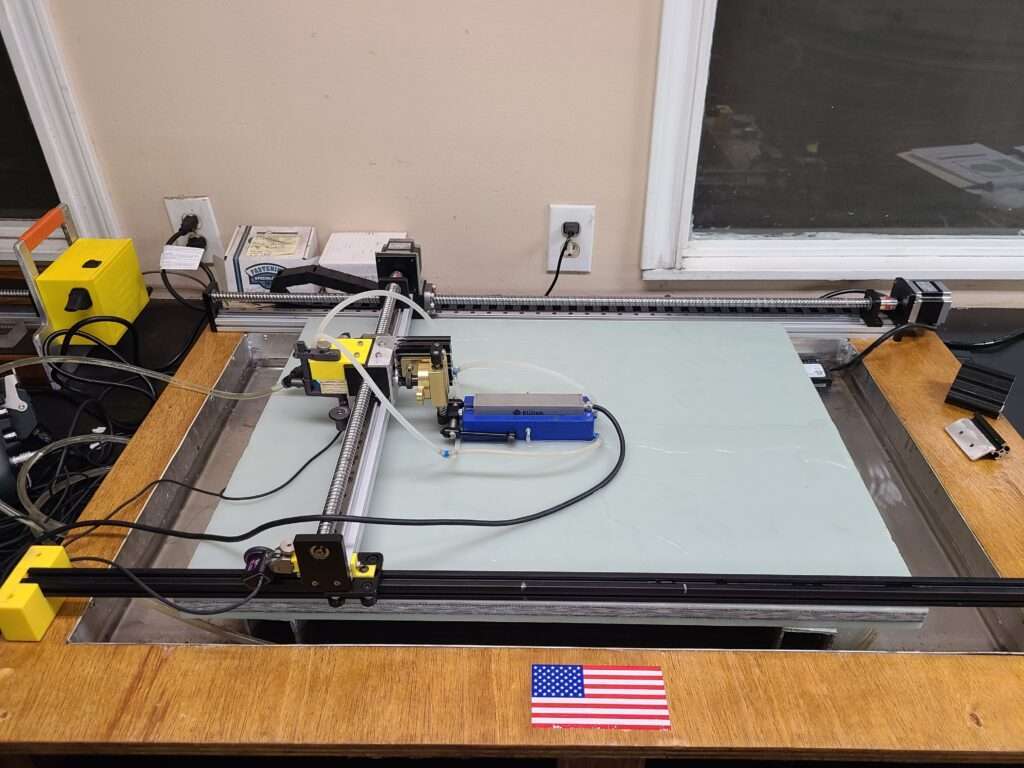

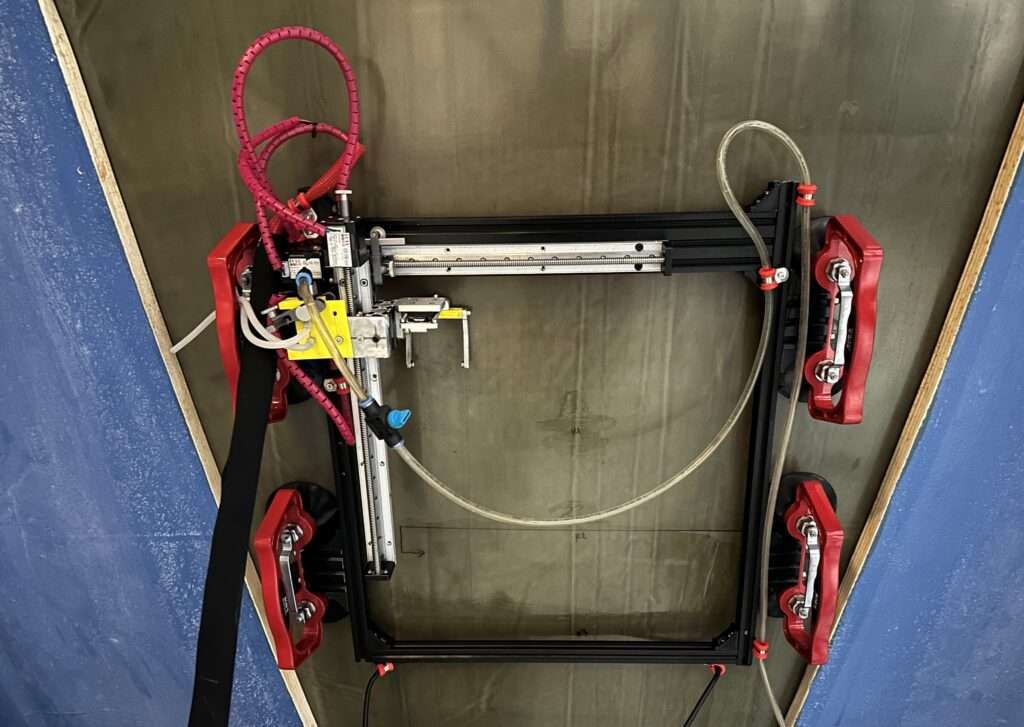

NDT Equipment Prototypes (Scanners)

Through decades of experience Mandina’s Inspection employs their expertise to design, fabricate, and implement NDT equipment prototypes. These prototypes aid in our commitment to quality inspections.

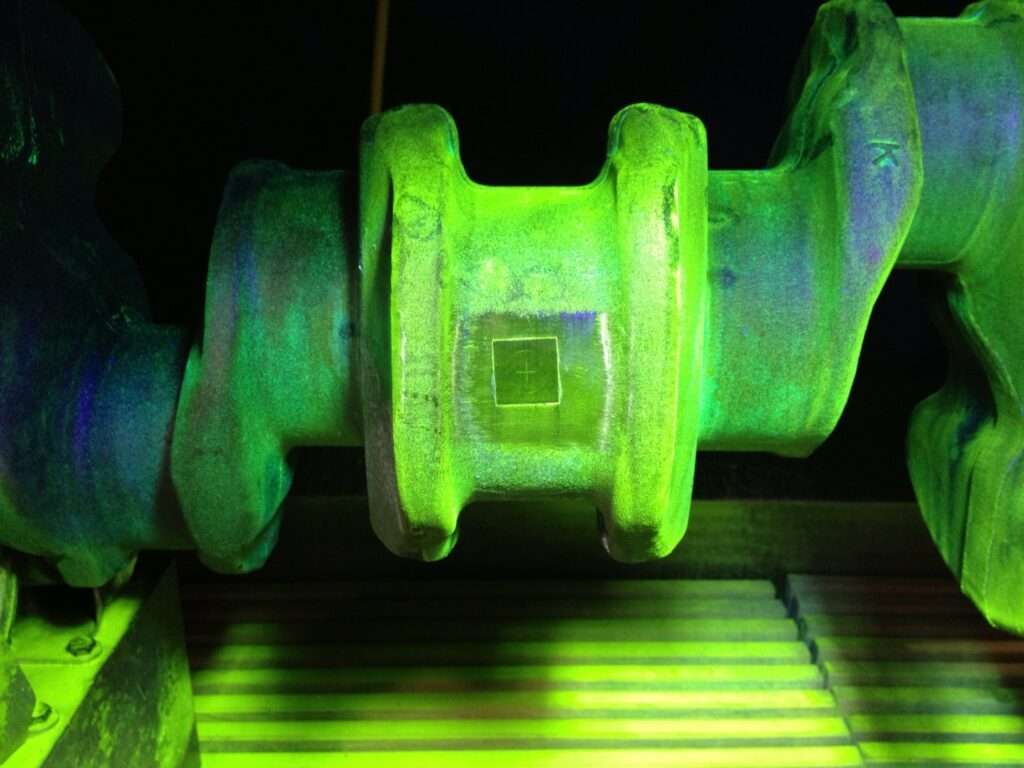

Calibration Blocks (EDM)

Not all inspections are created equal. Mandina’s Inspection offers an extensive variety of custom built calibration blocks to meet the unique demands of your NDT inspection scheme.

“Electrical discharge machining (EDM) is a non-traditional machining process based on removing material from a part through a series of repeated electrical discharges between tools called electrodes, and the part being machined in the presence of a dielectric fluid.”

– http://www.sciencedirect.com